UNIQUA AQUA J80-36-4"

| Voltage | 230 V |

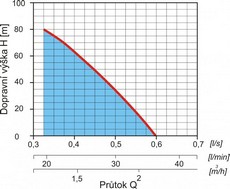

| Max. pump head | 100 m |

| Max. flow rate | 36 l/min |

| Max. immersion | 20 m |

| Nominal current | 4,2 A |

| Diameter suction housing | 1 " |

| Weight | 14,8 kg |

| Diameter pump | 92 mm |

| Working pressure height | 80 m |

Technical specifications

- submersible screw pump

- stainless steel and cast iron construction

- carbide mechanical seal SiC/SiC

- cable lengths of 20, 25, 30, 35, 40 meters

- max. diameter pump is 92 mm

- asynchronous electric motor with thermal winding protection

- starter box

Use

- pumping clean water from wells

- pumping clean water from underground bores

- irrigation system

- supply of households drinking water

The submersible pump UNIQUA AQUA is used to draw drinking water, clean water and industrial water. The pump is suitable for pumping clean water from wells, from bores with minimal diameter of 100 mm to supply of households and tanks, or can be used for irrigation system with the maximal immersion of 20 meters. This pump can't be used for pumping waste water. To use the pump for pumping flammable liquids, toxic liquid substance (acid, alkali) and all oil products is forbidden! To use the pump in a place danger of explosion and in swimming pools where people are in contact with water, is forbidden, too. When pumping industrial water, mineral water or mining water, the maximal allowed pollution quality and concentration of hydrogen ions in the water must be observed to support the durability and reliability of the pump. The producer can make pump with different cable lengths, in accordance with the with wish of the costumer. The maximal temperature of water for pumping is 35°C. The pump can be used in vertical, horizontal or tilted position.

Construction

The aggregate UNIQUA AQUA consists of a single-screw hydrostatic pump and a submersible electric motor. The primary parts of the pump are stator with a rubber filling and a spindle, which is rotated in stator. The electric motor is asynchronous and one-phase. The motor is protected against overheating by a thermal winding protection (the motor is protected against destruction for a short time). The user is obligated to protect the motor against overload by an overcurrent protection (motor starter). The connect cable is perfectly sealed by a special bushing and is protected against penetration of the pumped water. The intrusion of the water into the electric motor area is prevented by a mechanical seal and lip seal. The product is protected by the utility model and patent.

ČERPACÍ TECHNIKA s.r.o.

Gromešova 1905/30a621 00 Brno

| tel.: | +420 775 403 663 |

| mob.: | +420 776 694 693 |

| e-mail: | vyroba@cerpacitechnika.eu |